Laser engraving is a versatile and precise process that utilizes a high-power laser beam to etch or engrave a design onto a material’s surface. With its wide range of applications, it’s no surprise that laser engraving has become popular across various industries, from manufacturing to art. Choosing a high-quality laser engraving machine is crucial for achieving the best results and ensuring efficiency in your projects. In this guide, we will cover essential factors to consider when selecting a laser engraving machine, as well as tips for maintaining it and an overview of its applications.

Table of Contents

1. Understanding Laser Engraving Machines

A. Types of laser engraving machines

CO2 Laser Engravers – A laser beam is produced by these devices using a gas-filled tube and focused onto the material being etched. They work well for engraving non-metallic materials including leather, acrylic, and wood. The Longer RAY5 and the Sculpfun S30 Pro Max are two popular versions.

Fiber Laser Engravers – These machines use a solid-state laser to generate a high-powered beam that is ideal for engraving metal materials such as stainless steel and aluminum. They can also be used to mark plastics and some types of ceramics. Some popular models include the Triumph Fiber Laser Marking Machine and the MORN Fiber Laser Engraver.

Diode Laser Engravers – The low-power beam produced by these machines’ semiconductor lasers is perfect for engraving small objects like jewelry and electronics. They are also helpful for metal and some types of plastic marking. The NEJE Master 2 and the TEN-HIGH Mini Laser Engraver are two popular versions.

B. Components of a laser engraving machine

The primary components of a laser engraving machine include the laser source, the optics system, the control system, and the work table or bed. These components work together to deliver accurate and efficient engraving.

C. How laser engraving works

Laser engraving works by directing a high-power laser beam onto the material’s surface, which then evaporates or melts the material in a controlled manner. The result is a design or mark etched onto the surface.

D. Benefits of laser engraving

Laser engraving offers numerous benefits over traditional methods,which can be used on a wide range of materials:

Precision – A level of precision that is impossible to obtain with conventional techniques is offered by laser engraving. With the laser beam, elaborate patterns and minute details can be produced that are impossible to do with other techniques. Because of this, it is perfect for uses including jewelry creation, electronic components, and medical equipment.

Efficiency – The method of laser engraving is quick and effective. After the machine has been configured with the design, the engraving procedure may be carried out swiftly and reliably. It is therefore perfect for high-volume manufacturing runs because it requires less manual effort.

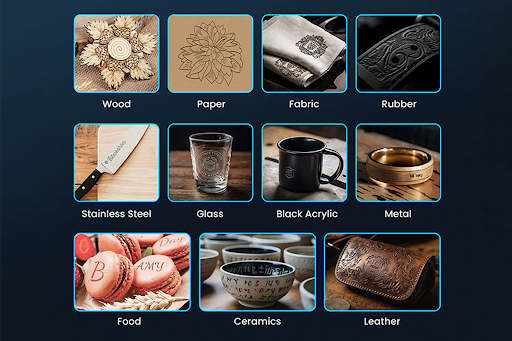

Versatility – A variety of materials, including wood, acrylic, leather, metal, glass, and polymers, can be engraved using a laser. As a result, it can be used in a wide range of industries, including manufacturing, advertising, and the arts.

Non-Contact -The laser beam does not make direct contact with the workpiece during the non-contact procedure of laser engraving. This increases control over the engraving process and lowers the possibility of damaging the material being etched.

Customization – Laser engraving allows for customization on a level that is difficult or impossible to achieve with traditional methods. It is easy to modify designs and make changes on the fly, which makes it ideal for creating one-of-a-kind or personalized items.

2. Factors to Consider When Choosing a Laser Engraving Machine

Before considering specific factors, it’s essential to identify your specific needs and requirements for a laser engraving machine. Some factors to consider include:

● Type of materials to be engraved

Different laser engraving machines are suited for different materials. For example, CO2 lasers are better for organic materials like wood, while fiber lasers are better for metals.

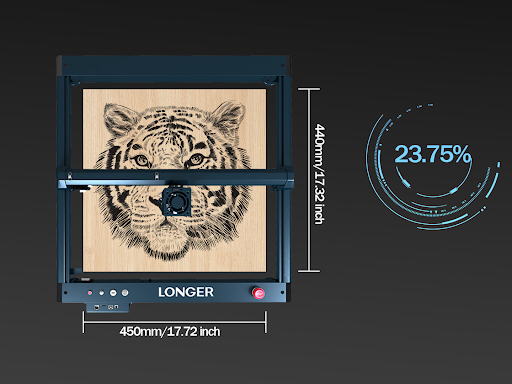

● Size of the workpiece

The size of the workpiece should dictate the size of the worktable or bed, as well as the machine’s overall dimensions.

● Wattage and power of the machine

Higher wattage machines offer faster engraving speeds and can handle thicker materials. However, they may also be more expensive and require more power to operate.

● Type of laser source

As mentioned earlier, there are different types of laser sources (CO2, fiber, diode), each with its strengths and weaknesses. Choose the one best suited for your specific needs.

● Cooling system

A good cooling system is crucial for maintaining the machine’s performance and longevity. Options include air cooling and water cooling systems.

● Software compatibility

Ensure that the laser engraving machine is compatible with the software you plan to use for designing and controlling the engraving process.

● Maintenance and support

Look for a machine that is easy to maintain and comes with good customer support from the manufacturer.

● Budget limitation

Finally, consider your budget and choose a machine that offers the best value for your money without sacrificing quality.

3. Applications of Laser Engraving Machines

Engraving and etching

Laser engraving machines can be used to create intricate designs and patterns on various materials, including wood, metal, glass, and more.

Cutting and shaping

In addition to engraving, laser machines can also be used to cut and shape materials with precision.

Marking and labeling

Laser engraving machines can be used to mark and label products and components in industries like manufacturing, electronics, and medical.

Creating 3D designs and models

Some laser engraving machines can create 3D designs and models, making them ideal for industries such as architecture and art.

4. Tips for Maintaining Your Laser Engraving Machine

- Regular cleaning and maintenance

Keep your laser engraving machine clean and well-maintained to ensure optimal performance and longevity.

- Proper storage and handling

Store the machine in a clean, dry environment and handle it with care to avoid damaging the sensitive components.

- Troubleshooting common issues

Familiarize yourself with common issues that may arise during operation and learn how to troubleshoot them effectively.

- Recommended accessories and tools

Invest in quality accessories and tools to enhance the performance and capabilities of your laser engraving machine.

5. Conclusion

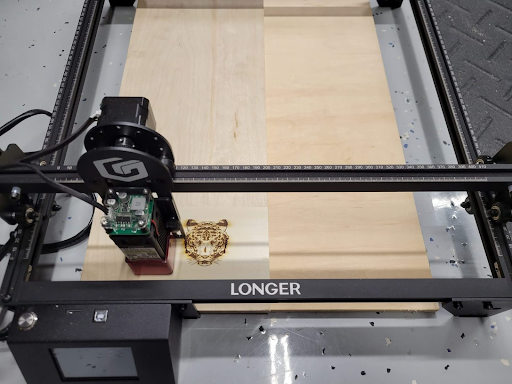

Choosing a high-quality laser engraving machine requires careful consideration of factors such as the type of materials to be engraved, the size of the workpiece, the machine’s wattage and power, and the type of laser source. By keeping these factors in mind and maintaining your machine properly, you can ensure efficient and precise engraving for your projects. As laser engraving technology continues to advance, we can expect even more innovations and capabilities in the future. Some popular laser engraving machines to consider include the GearBerry Laser Engraver. By selecting the right machine and maintaining it well, you can unlock the full potential of laser engraving and bring your projects to new heights.

The brand, GearBerry, specializes in providing high-quality laser engraving machines to meet the needs of professionals and hobbyists alike. Their machines are designed to offer precise and efficient results on a variety of materials, including wood, acrylic, leather, and more.

Whether you’re a small business looking to increase efficiency or a hobbyist looking for a new creative outlet, GearBerry is here to help. The team is dedicated to providing exceptional customer service and support.