Table of Contents

What are metals?

A metal is a material that displays a radiant appearance when newly ready, cleaned, or squashed and is portrayed by high electrical and warm conductivity, flexibility, malleability, and high light reflectance. These properties are the aftereffect of metallic holding between metal iotas or atoms.

Metal can be a substantial component like iron, a combination like tempered steel, or sub-atomic mixtures like polymeric sulfur nitride.

Around 3/4 of all realized compound components are metals. The most plentiful in the world’s covering are aluminum, iron, calcium, sodium, potassium, and magnesium. Most metals are tracked down in minerals (minerals), yet some, like copper, gold, platinum, and silver, are often found in the free state since they don’t promptly respond with different components.

15 types of metals:

The metals can be separated into two fundamental gatherings: ferrous metals are those which contain iron, and non-ferrous metals are those which have no iron.

Following are the various sorts of Metal:

- Steel.

- Carbon Steel.

- Composite Steel.

- Treated Steel.

- Iron (Fashioned or Cast)

- Aluminum.

- Magnesium.

- Copper.

- Metal.

- Bronze.

- Zinc.

- Titanium

- Tungsten

- Nickel

- Cobalt

Iron :

Iron, which makes up around 5% of the world’s hull and is the 6th most bountiful component on the planet, is an exceptionally plentiful and highly healthy known kind of Metal. Unadulterated iron is an unsteady component that effectively responds with oxygen in the air to frame iron oxide. It is generally alloyed with different elements to make steel more steady.

Steel :

Adding carbon to the press to some extent, beats these shortcomings. This combination of iron and carbon is partially known as carbon steel. Adding carbon to the media makes it much more grounded and gives it other incredible properties.

It is likely the most bountiful Metal in the advanced world. By definition, steel is iron (a component) blended in with carbon. This proportion is typically close to 100% iron and 1% carbon; however, this proportion can change somewhat.

Following are the more metal types:

Aluminum :

Aluminum, for the most part, is getting from bauxite metal. Light, solid, and utilitarian. It is the most normal Metal on the planet, and its utilization is all over.

That is because of properties, for example, strength, lightweight, erosion obstruction, electrical conductivity, and the capacity to shape composites with most metals. Likewise, it is non-attractive and straightforward to process.

To the extent that Metal goes, it’s genuinely present-day Metal. Aluminum was first delivered in 1825 and has been the premise of extraordinary accomplishments from that point onward.

Magnesium :

Magnesium is a genuinely great metal. Its weight is around 2/3 of aluminum, and it has similar strength. Consequently, it is turning out to be more famous step by step. Frequently this shows up as a compound. It implies blending it with metals and different components to make half-and-half materials with extraordinary properties. This likewise makes it more straightforward to use in assembling processes.

One of the most well-known utilizations of magnesium is in the auto business. Magnesium is viewed as a move forward from aluminum in weight decrease with high strength and is cosmically less expensive.

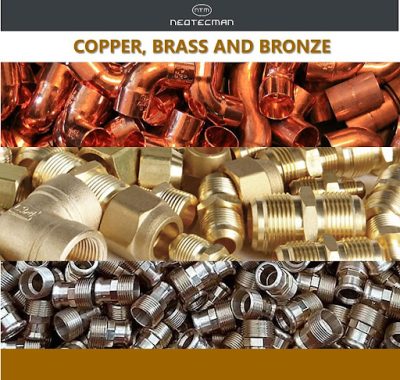

Coppor :

While discussing various metals, copper and its amalgams can’t be disregarded. It has a long history since it is not difficult to form. Today, it is as yet a significant metal in the industry. There is no such thing as it in nature in its unadulterated structure. Accordingly, purifying and extraction from Metal are vital.

Metals are incredible conveyors, and copper stands apart from the rest. Because of its brilliant electrical conductivity, it is utilized as a conduit in electrical circuits. Its conductivity is second just to silver. It likewise has excellent warm conductivity. Hence, many cooking tools are made of copper.

Brass :

Brass is an amalgam of copper and zinc. The subsequent yellow Metal is precious for some reasons. Its brilliant variety makes it exceptionally famous for fancy purposes. This Metal is generally found in classical furniture handles and handles.

How much every Metal is different depending upon the Metal’s ideal electrical and mechanical properties. It contains modest quantities of other metal components like aluminum, lead, and manganese.

Metal is excellent for low-contact applications like locks, courses, funneling, instruments, apparatuses, and frills. It is fundamental for characteristically safe applications to forestall ignites and empower use in explosive conditions.

Bronze :

Bronze is additionally an amalgam of copper. In any case, bronze contains tin rather than zinc. The expansion of different components, for example, phosphorus, manganese, silicon, and aluminum, might work on its properties and appropriateness for explicit applications.

Bronze is fragile, complex, and impervious to weakness. It additionally has magnificent electrical conductivity, warm conductivity, and erosion obstruction. Bronze is utilized to make mirrors and reflectors. Used for electrical associations. Because of its erosion obstruction, it is utilized for submerged parts and boat extras.

Zinc :

Zinc is a metal available everywhere and has numerous applications in clinical and modern areas. Zinc is a highly regular metal utilized in coatings to safeguard different metals. For instance, it’s generally expected to see excited steel, which is fundamentally steel covered with zinc to assist with forestalling rusting. Zinc is likewise used to bite the dust castings for electrical, equipment, and auto enterprises.

Because of the low electrochemical capability of zinc, its applications incorporate marine applications to forestall the consumption of different metals by cathodic assurance. Conciliatory zinc anodes might safeguard valves, pipelines, and tanks.

Titanium :

Titanium is a significant design metal since it is solid and light. It likewise has high warm security even at temperatures over 480 degrees Celsius. These elements are utilized in the airplane business.

Military hardware is one of the instances of the utilization of this Metal. Titanium is likewise utilized in clinical applications because of its superb erosion obstruction. Titanium is again used in the synthetic business and sports merchandise.

Tungsten :

Tungsten has the most noteworthy softening point and the highest rigidity of every unadulterated Metal. This makes it extremely helpful.

About a portion of all tungsten is utilized to make tungsten carbide. It is a rigid material used in cutting devices (mining and metalworking), abrasives, and heavy gear. Effectively cuts titanium and high-temperature superalloys.

Nickel :

Nickel is an exceptionally standard component that is utilized all over. Its most normal use is in the creation of hardened steel, where it expands the strength and consumption obstruction of metals. Almost 70% of the world’s nickel is utilized to make treated steel.

Strangely, nickel makes up 25% of the piece of the US five-penny coin. Nickel is likewise a typical metal utilized in plating and alloying. It tends to be used to cover lab and compound hardware as well as whatever requires an extraordinarily smooth and clean surface.

Cobalt :

Metal has for some time been utilized as a blue shade in colors and paints. Today, it delivers high-strength and wear-safe steel combinations. Cobalt is seldom mined alone and is a result of copper and nickel creation.

Tin :

Tin is genuinely delicate and pliant. It is an alloying component to make things like bronze (1/8 tin, 7/8 copper). It is likewise the fundamental part of pewter (85-close to 100%). At the point when you twist a tin bar, it makes a sound called a “tin cry.” This is the turning sound when the gem structure redesigns itself called twinning.

LEAD :

Lead is highly delicate, pliant, and exceptionally thick and weighty. It likewise has a generally low liquefying point. Lead Metal has high machinability and significant consumption opposition. Channeling and painting show numerous purposes.

Lead was utilized as an enemy of thump specialists in gas. This lead side-effect was subsequently observed to be answerable for unexpected severe problems. Today, information is standard in ammo, vehicle batteries, radiation protection, hard work, and link sheathing.

During the 1800s, it was found that lead is very harmful. Accordingly, it’s not exceptionally usual in current times, but rather it wasn’t so much that quite a while in the past that it was as yet found in paint, projectiles, and so forth.

Silicon :

Silicon is a semi-metal. This implies that it has both metallic and non-metallic properties. For instance, it seems to be Metal. It is rigid, gleaming, bendable, and has a high softening point. That is important for the explanation; it’s not viewed as full Metal.

In any case, it is a typical component tracked down in metals. At the point when utilized in alloying, it can altogether change the properties of metals. For instance, adding silicon to aluminum makes welding more straightforward.

Chromium :

Chromium is the second hardest essential component after carbon, likely jewel. It is usually utilized as an amalgam to work on the strength of different metals.

The softening place of the Metal ultimately depends on around 2000 degrees Celsius. Chrome has a special intelligent appearance and can be utilized to upgrade the outer layer of different metals.

Lithium :

Lithium is characterized by delicate Metal or soluble metal base gathering. It has an appealing silver-white shine. Lithium is utilized to work on the strength of glasses and ceramics.

Pros of Metals

Most of the apparatus ran on metal parts and was intended to be worked around metal parts. That commonality and typical practice make it much simpler to find new pieces if one requires supplanting. A few other geniuses of metal parts are:

- Higher elasticity than plastic

- Preferable intensity opposition over plastic

- Less expensive in high volume and long haul creation

- More straightforward to clean

Cons of Metals

Producing metal parts routinely implies depending on vigorously burdened metal providers. Retaining the expense of unrefined components is reflected in a higher cost for each region, making it harder for organizations to legitimize purchasing expensive pieces. A few different cons of metal parts are:

- Longer post-creation getting done, for example, deburring and painting

- Harder to machine assuming that crisis changes are required

- Harder to make complex pieces because of specific metal viscosities

Metal laser cutting

Metal laser cutting is the most reliable cycle for exact cuts on any material. Metal laser cutting uses a powerful laser to slice materials to correct determinations in the controlling programming of the Metal laser cutting machines. The product changes the computerized settings and manages by the laser for spotless and exact cuts. Laser changing over applications perform through cuts, kiss-cuts, laser holes, scores, laser carves, laser removals, laser welding, and penetrating.

Metal laser cutting is a considerably more effective cycle than mechanical tooling and reducing since it expenses less and is significantly more precise. The computerized control considers limitless cutting ways and simple cutting, such as changes that would not be functional on a mechanical machine. The laser plays out the cut by dissolving, consuming, or disintegrating away the material and leaving a sharp, clean edge. Materials that can be handled by Metal laser cutting incorporate endlessly paper boards, cement tapes, plastics, films, textiles, abrasives, metals, and photovoltaics.

Two fundamental sorts of lasers are utilized for cutting administrations: the CO2 laser and the YAG laser. The CO2 laser is used for cutting, exhausting, and etching. These lasers utilize radio recurrence energy and are used for modern cutting gentle steel, aluminum, treated steel, titanium, paper, wax, plastics, wood, and textures. CO2 lasers have four unique variations, quick hub stream, slow hub stream, cross-over stream, and chunk. Pivotal stream resonators flow a combination of carbon dioxide, helium, and nitrogen with a turbine or blower at various speeds. Cross-over stream lasers course blend many increasingly slow resonators with static gas handles that don’t need compression. YAG lasers are utilized for highly high-power exhausting and etching. YAG lasers are sufficiently robust to imprint significant areas of strength like metal and pottery.

Laser radiates are created by invigorating the lasing material, CO2, at times, with electrical releases or lights inside a shut region. When the material is animated, the bar is bounced off a fractional mirror until it assembles sufficient energy to escape as a noticeable light shaft. This light bar is coordinated to a focal point that centers the bar. The post is utilized to make a puncture before cutting. During cutting, the heading of the bar polarization should be turned to guarantee a smooth edge. The two primary techniques for cutting are vaporization and softening and blow. Vaporization cutting proposes the intensity of the laser to carry the surface to its limit and consume an opening. The opening extends as the fume disintegrates the walls of the space. Vaporization cutting is excellent for material that doesn’t dissolve, like wood, carbon, and thermoset plastics. With liquefy and blow cutting, the material is warmed until it softens, and a gas stream floors the dissolved part. This is a typical interaction for cutting metals.

metal casting

The projecting of metal was an old technique that comprises different reasons and applications. Advancements from the past until these current days have been using metal functions as the method involved with making strict, creative, and some other viable things. The metal casting strategy incorporates liquefying metals at high temperatures and using molds to shape metals into another thing.

It is a type of metal casting that is becoming well known as the assets become reasonable and individuals get up to sharing data, tasks, and thoughts. It additionally needs specific stuff, inventiveness, and information.

Projecting iron requires a few particular types of gear, information, and inventiveness. Many individuals partake in the metal cast as a leisure activity and an imaginative undertaking. Two inspirations stand apart for why individuals take part in metal casting. The principal reason is individuals’ need to make parts or things for specific endeavors. The subsequent inspiration involves metal giving a role as a way to create figures and other imaginative exercises.

Whatever the explanation, somewhat level iron appears appealing since it tends to be made at home, either in the studio or on the patio. Individuals who work on metal projecting can make instruments and gear at home, like heaters and molds. Metal castings are restricted simply by the people’s cravings, so for the people who have the need and time, anything is conceivable for all intents and purposes.

The substantial projecting cycle on metal casting has different structures, with sand projecting being the most well-known. Sand projecting takes part in making a form made of sand that can be ready at home, and afterward, liquid metal is poured into the shape. Later, the metal is allowed to air dry, and the form is withdrawn. This projection is the most practical, yet different castings can give total subtleties and raised quality outcomes.

The most common way of softening iron is difficult since iron projecting utilizes metals in its liquid structure. The liquefying point of iron is over 1,000 degrees Fahrenheit or 530 degrees Celsius. Anyone who needs to work in metal projecting must play it safe. Some security advice should be placed as the main priority, like the accompanying: Don’t gaze straight to powerful flares; Blast is responsible if liquid metals contact a nonporous surface with water; showering hot metals all over. The utilization of legitimate well-being gear like goggles and gloves is required too.