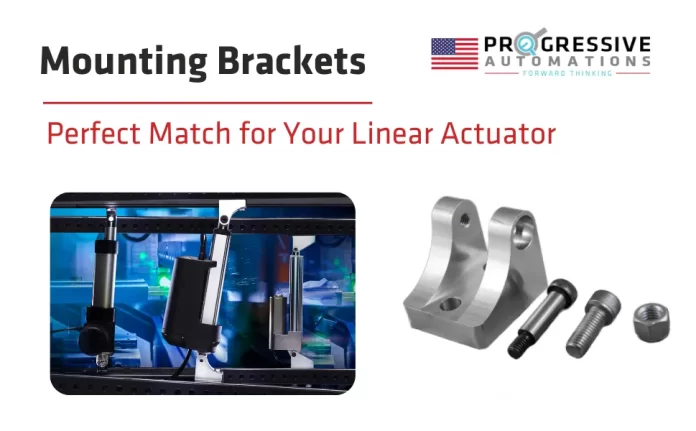

In the ever-evolving world of technology, linear actuators have taken center stage as versatile tools that translate rotational motion into linear movement. These remarkable devices have found their place in a great diversity of applications. Their effectiveness, however, often hinges on a seemingly humble yet vital component – the mounting bracket.

In the linear actuator setups, the significance of mounting brackets cannot be overstated. These unassuming components play a pivotal role in ensuring stability, adaptability, and precision. By customizing mounting brackets to fit specific needs, you can optimize the performance and efficiency of your systems. Unlock the full potential of your linear actuator setup with customized mounting brackets.

Table of Contents

What Are Linear Actuators Used For

Linear actuators are devices that serve as the bridge between rotational motion and linear motion. It allows them to find many applications for different tasks across various industries. They are indispensable in automating processes, enabling precise movements, and enhancing the overall functionality of systems.

What is the Purpose of Mounting Bracket?

The effectiveness of a linear actuator often depends on its secure attachment to the intended structure or application. It is where mounting brackets step in.

They serve as the interface between the linear actuator and the object it is meant to move. While their role may appear straightforward, mounting brackets are integral to optimizing performance, ensuring stability, and adapting linear actuators to specific needs.

Types of Linear Actuator Mounting Brackets

Linear actuator mounting brackets come in various types, each tailored to specific applications and requirements:

Fixed Mounting Brackets

Fixed mounting brackets provide a stable and rigid connection between the linear actuator and the mounting surface. They are often used in applications where a fixed, unchanging position is required.

Pros & Cons

- Fixed brackets excel in stability but may lack adaptability;

- They are ideal for scenarios where precision and rigidity are paramount;

- They may not suit applications that require variable positioning.

Adjustable Mounting Brackets

Adjustable mounting brackets offer flexibility by allowing users to change the position of the actuator along a predefined range. They are suitable for applications requiring variable positioning.

Advantages and Disadvantages:

- They offer versatility;

- They may sacrifice some stability compared to fixed brackets;

- They are an excellent choice for applications demanding flexibility and adaptability.

Swivel Mounting Brackets

Swivel mounting brackets enable rotational movement of the linear actuator while maintaining a secure connection. They are ideal for applications demanding both linear and angular movement.

Pros & Cons

- They provide the ability to change position and orientation;

- They are suitable for applications requiring precise positioning in various directions;

- They may be less stable than fixed or adjustable brackets in some scenarios.

Factors to Consider When Choosing a Mounting Bracket

Selecting the right mounting bracket for your linear actuator involves careful consideration of several factors:

- Load capacity. Understanding the weight and force requirements of your setup: determine the maximum load your actuator will bear and assess the force it needs to exert to achieve your desired movements;

- Matching the load capacity of the mounting brackets. Ensure that the chosen mounting brackets can safely support the weight and force requirements of your application to prevent overloading and potential damage;

- Installation ease. Evaluate how straightforward it is to install and adjust the mounting brackets, especially if you have limited mechanical expertise;

- Compatibility with the linear actuator model. Confirm that the selected brackets are compatible with your specific linear actuator model to ensure seamless integration;

- Range of motion. Assessing the Required Range of Motion for Your Application: Determine the extent of movement your application demands and whether it requires a fixed, adjustable, or swivel bracket;

- Choosing mounting brackets with suitable adjustability or swivel capabilities. Select mounting brackets that align with the required range of motion to achieve precise positioning;

- Environmental factors. Consider environmental factors such as temperature, moisture, and exposure to corrosive substances;

- Selecting mounting brackets made from appropriate materials for durability. Choose brackets constructed from materials that can withstand the environmental conditions of your application to ensure long-term durability.

Applications of Customized Linear Actuator Mounting Brackets

Customized linear actuator mounting brackets find applications across various industries. Here are some of the most prominent use cases:

Home Automation

In home automation, customized mounting brackets play a pivotal role in motorized furniture (e.g., adjustable beds, recliners) and automated lighting systems.

How do mounting brackets play a crucial role in these applications? Mounting brackets enable precise positioning of linear actuators, allowing furniture or lighting fixtures to adjust according to user preferences.

Industrial Automation

Using mounting brackets for automated machines or processes in industrial settings is essential for automated machinery, conveyor systems, and robotic arms. These devices also impact efficiency and safety in industrial settings.

Properly customized mounting brackets ensure the safe and efficient operation of automated systems. They reduce downtime and enhance productivity.

Automotive Modifications

In the automotive world, customized brackets find application in the following mechanisms:

- Convertible roof mechanisms;

- Trunk openers;

- Other vehicle enhancements.

Within these mechanisms, customized mounting brackets allow for precise control of linear actuators. They contribute to the convenience and functionality of automotive modifications.

Tips for Mounting Brackets Proper Installation and Maintenance

To ensure the optimal performance and longevity of your customized linear actuator mounting brackets, you should follow a few simple but essential tips:

#1. Ensure correct alignment and positioning of mounting brackets

Proper alignment and positioning are critical for optimal performance. Ensure that brackets are securely fastened and aligned with the linear actuator and mounting surface.

#2. Regular inspection and lubrication for smooth operation

Periodically inspect the brackets for wear, damage, or loose fasteners. Lubricate moving parts to ensure smooth operation and minimize friction.

#3. Check for wear or damage to brackets over time

Keep an eye on the condition of the brackets over time and replace those components that show signs of wear or damage to maintain reliability and safety.

The world of linear actuator mounting brackets is a realm where precision meets innovation. Whether you automate your home, optimize industrial processes, or embark on automotive modifications, the choice of customized mounting brackets can make all the difference.