Ventilation of your roof space is an important consideration, especially in modern times. Adequate ventilation of your roof covering is vital for reducing the risk of condensation build-up and damp, and there are clear requirements and building regulations for proper ventilation for a variety of roof types and roof covering options. These regulations are designed to provide ventilation to roof spaces and reduce the chances of condensation and damp to protect buildings and their contents. So make sure you use a good roofing company.

Table of Contents

Why do we need roof ventilation?

As we have become more conscious of our energy efficiency and use, we have found more and more effective methods of insulation. At the same time, we are also using more heated appliances as well as heating systems that more effectively heat our homes.

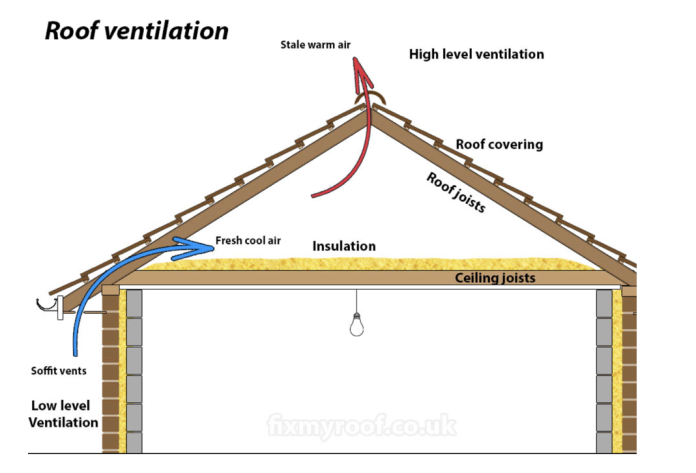

When you put better insulation and higher heat levels together, this can add up to a big problem with condensation and damp. Condensation is created when warm air hits cold surfaces. If your home is well insulated, when the hot air reaches the roof space, it will hit the cold air surfaces and create water droplets on the joints and beams. This water can then drip down and eventually cause damp in your home’s structure and inside the rooms.

If it is left, the condensation and damp can cause structural issues to your home due to rot, it can cause the exterior rendering to crack, damage your belongings because of mould, and can even cause health problems due to breathing in mould spores. All of this can be avoided by providing a way for water vapour to escape through decent roof ventilation.

What are the roof ventilation requirements?

The NHBC Standards lay out clear recommendations for the ventilation of a roof space. These requirements are in line with the Building Regulation Approved Document C2 – BS 5250. According to these requirements, new roofs must have adequate precautions against condensation and cold. Before we dive into the requirements themselves, we need to define a few terms.

Cold roofs

This is a roof space where the insulation is laid directly upon a horizontal ceiling level.

Warm roofs

These are roofs where insulation is laid between or above sloping rafters.

Low resistance (LR) underlays

This is an underlay that is vapour permeable.oo

High resistance (HR) underlays

This is an underlay that is vapour impermeable.

BS 5250 minimum requirements for a cold roof void

Size of ventilation openings

The ventilation openings should be small enough that birds aren’t able to enter. Between 3mm and 10mm is acceptable.

Ventilation paths

To be in accordance with requirements, there should be clear ventilation paths. This can include ensuring that there is a spacer in the eaves ventilation and to install insulation above and beyond the wall plate that doesn’t block the ventilation path.

Pitched roofs

Under certain conditions, for pitched roof installations, there should be ridge ventilation openings (or high-level ventilation) that is equivalent to a continuous opening of 5mm at the highest point of the roof slope. These include:

- an unventilated cold roof has insulation placed over a horizontal ceiling and there is a vapour-permeable (LR) underlay.

- a vapour-permeable underlay is used on a sloping roof that has areas covered in a non-permeable material

- the roof is covered with vapour impermeable (HR) and the pitch exceeds 35 degrees or is longer than 10m. This should be in addition to eaves ventilation.

High resistance (HR) underlays

To comply with BS 5250, if the roof space has high water vapour resistant underlay, eaves ventilation needs to be provided on the opposite sides to allow for cross ventilation. In addition to this:

- If the roof pitch is 15 degrees or more, there needs to be ventilation that is equivalent to a 10mm slot and this needs to run the full length of the eaves.

- If the ceiling follows the slope of a pitched roof, ventilation that is equivalent to a 25mm slot should be provided that runs the full length of the eaves. This is also the case if it is a cold roof with a pitch that is less than 15 degrees.

- For mono-pitched roofs, there should be cross ventilation installed and there should also be high-level ventilation that is equivalent to a 5mm slot, as well as eaves ventilation.

Moist air leakage

Prevention of moist air leakage should be taken which can include ensuring any gaps in the roof area are sealed and making sure that any downlighters are also specified and sealed.

Vapour control layers

A vapour control layer should be installed under some circumstances. For example, it should be installed for a roof construction that has a ceiling board that is fixed to the rafters. If a vapour control layer is used in the roof construction it should be placed on the warm side of the roof space.

Access hatches

Precautions need to be taken for access hatches (including loft hatches) to cold roof voids to ensure that they are properly sealed and there is no air leakage. Proprietary hatches should be installed in accordance with the manufacturer’s instructions and any hatches should help to contribute to the thermal insulation.

Pipework

Pipework should be properly insulated and should ideally be below the insulation of the roof construction.

Warm roof requirements

All of the requirements and building regulations above refer to cold roofs. Warm roofs are specifically designed to prevent moisture from forming on the pitched roof cold surfaces. For this reason, ventilation isn’t usually required for warm roof construction projects. There should, however, be an air and vapour control layer installed or a vapour barrier on the warm side of the pitched roof structure.

Additional ventilation

It is entirely possible to add additional ventilation to roof coverings for pitched roofs. Extra ventilation openings can ensure that pitched roof spaces are properly ventilated and can reduce the chances of harmful condensation and damp problems.

Additional ventilation options will usually involve adding extra vents to the roof structure itself. The most popular option is to add vents within the roof ridge or the eaves. This helps to create a flow of air around roof voids.

Other options include ensuring breathable felt is used in the roof void and roofing underlay, replacing some roof tiles with tile vents, and installing over fascia vents that lie over the fascia but under the eaves (the whole length of the eaves).

The bottom line

Prevention of condensation is key to keeping a building free from damp and other damage that can arise from water vapour and moisture getting into the building structure. Most buildings nowadays have high-performance insulation in their ceiling level and this can contribute to rising levels of interstitial condensation (condensation within an enclosed wall roof, or cavity) damage.

If you can ventilate your roof space per the regulations, this won’t take anything away from the thermal performance of the insulation but it will reduce the chances of condensation build-up.